At 3D Industrial Services, we provide laser shaft alignment services designed to enhance the performance and longevity of your rotating machinery. Proper shaft alignment is critical for minimizing wear, reducing maintenance costs, and ensuring peak equipment life. Using advanced laser alignment tools, our technicians deliver precise alignment solutions that prevent shaft misalignment, which can lead to unexpected breakdowns and costly downtime.

By implementing precision laser alignment, we ensure that your shaft alignments are within tolerance, improving efficiency and extending the service life of your machinery. Whether you need alignment for turbines, compressors, or other rotating equipment, our laser alignment system provides the most accurate alignment available.

Reduce mainteance costs

Proper laser shaft alignment is essential for reducing unnecessary wear and tear on bearings, couplings, and rotating shafts. A misaligned shaft coupling leads to increased friction, excessive vibration, and premature equipment failure.

Extends the life of bearings and couplings: Shaft misalignment increases strain, reducing the service life of key components.

Reduces maintenance costs : Accurate alignment prevents excessive wear, lowering the frequency of repairs and part replacements.

Minimizes downtime: Well-aligned rotating shafts reduce unexpected breakdowns, keeping your operation running smoothly.

Improve Machinery Performance and Energy Efficiency

Shaft laser alignment services are vital for ensuring optimal machinery performance and reducing energy consumption. Shaft misalignment creates additional load, requiring more power to maintain operation.

Lowers power consumption: Well-aligned shaft couplings reduce energy waste, leading to cost savings.

Enhances machine uptime: Proper alignment increases the efficiency and reliability of your rotating machinery.

Improves performance: Precision alignment reduces friction and vibration, allowing for smooth operation and improved productivity.

Prevent Costly Damage and Improve Safety

When a machine is installed with misaligned shafts, it can cause excessive stress on components, leading to severe failures. Proper shaft alignment procedures prevent catastrophic damage and improve workplace safety.

Prevents axial and radial stress: Shaft misalignment causes undue stress on bearings and other critical parts.

Avoids catastrophic failures: Precise alignment methods help detect issues before they lead to significant damage.

Enhances worker safety: Misaligned equipment poses risks such as excessive vibration, component failure, and hazardous operating conditions.

Why Choose Us

At 3D Industrial Services, we specialize in laser shaft and machine alignment to provide the best possible results for your equipment.

Utilization of advanced laser alignment equipment: We employ the latest laser alignment tools, including Rotalign, Optalign, and Pruftechnik technologies.

Experienced and certified technicians: Our experts ensure accurate shaft alignment with minimal disruption to operations.

Comprehensive alignment solutions: We tailor our alignment services to suit your specific industry needs.

Commitment to precision and efficiency: Our alignment process ensures accurate alignment and improved alignment results.

Our Detailed Shaft Alignment Process

Our engineering services utilize state-of-the-art laser alignment techniques to provide the highest level of precision for your machinery. With laser-based alignment tools, we ensure that every component operates at peak efficiency, reducing wear and maximizing uptime.

Initial Inspection and Data Collection

We begin by assessing the current alignment measurements and alignment data of your rotating machinery and identifying any signs of shaft misalignment.

Precision LaserAlignment Execution

Using the most precise laser alignment tools, we carefully align shafts to meet the required tolerance levels, ensuring smooth operation. We utilize laser shaft alignment systems for both horizontal and vertical applications.

Alignment VerificationAnd Adjustments

We perform post-alignment checks using laser alignment equipment to confirm that all alignment results are within specifications. This step ensures coupling alignment and maintains operational integrity.

Final Reportand Recommendations

Our team provides a comprehensive report detailing the alignment solution applied and any additional maintenance suggestions. We also assess the alignment of two or more rotating shafts to ensure optimal equipment efficiency.

Types of Laser Shaft Alignment Services

Our alignment services cater to a wide range of machinery applications:

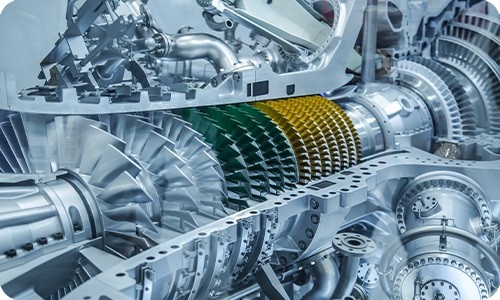

Turbine and Compressor Alignment

Proper alignment of turbines and compressors is crucial for maintaining operational stability and preventing costly downtime. Misaligned turbines or compressors can suffer excessive vibration, elevated temperature issues, and premature component failure. Our advanced laser alignment systems provide precise alignment for these critical rotating machinery components, enhancing reliability and extending service life.

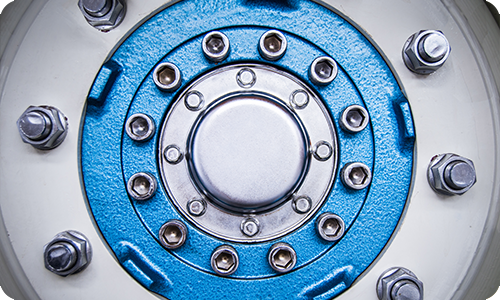

Coupling Alignment

Coupling alignment is essential for efficient transmission of power between rotating shafts. Our precision laser alignment ensures shaft coupling accuracy, significantly reducing vibration and mechanical wear. We utilize advanced alignment tools to measure and correct misalignment conditions across coupling halves, ensuring smooth, efficient power transmission and prolonged equipment life.

Bearing Alignment

Bearings are integral components whose reliability directly impacts overall machinery performance. Precise laser alignment minimizes bearing stress, reducing vibration and friction, which are leading causes of bearing failure. Our specialists meticulously align bearings to ensure proper operation, enhancing equipment reliability and extending bearing lifespan.

Why Accurate Alignment Matters

Precision alignment is critical because even minimal misalignment can lead to significant operational issues. Angular and axial misalignment of rotating shafts contributes directly to increased energy consumption, excessive wear on critical components, and eventual equipment failure. Proper alignment ensures machinery runs smoothly, safely, and efficiently, contributing to a lower total cost of ownership.

Precision alignment services provide significant benefits, including reduced energy consumption, improved equipment performance, and extended machinery life. Accurate alignment reduces mechanical stress, decreases energy consumption, and improves overall equipment reliability. By investing in professional laser shaft alignment services, facilities can ensure sustained operational excellence and productivity.

FAQ About Shaft Misalignment Services

It depends on your equipment usage, but we recommend performing shaft alignments during routine maintenance checks or after any major repair or installation.

Optimize Performance

Optimize Performance with Expert Laser Shaft and Machine Alignment

If you're experiencing issues with shaft misalignment or need an expert alignment service, contact us today. Our team at 3D Industrial Services is ready to provide reliable laser shaft alignment services that ensure optimal machinery performance and extend your equipment's service life. Our experts use laser technology and alignment methods to provide the best results. Don't let misalignment impact your operations—used to align all critical machinery, our services help maintain efficiency and reliability.