Achieve optimal reliability and efficiency in your power generation systems with 3D Industrial Service’s specialized gas and steam turbine alignment services. Our precision turbine alignment methods ensure turbine components, including rotor and stator, casings, and bearings, remain within acceptable tolerances, avoiding casing slippage, rotor misalignment, and unnecessary partial disassembly.

Proper turbine alignment is essential in maintaining operational efficiency, extending equipment lifespan, and reducing the likelihood of costly downtime. Misalignment, even minimal, can lead to vibration, excessive wear, blade rubs, compressor inefficiencies, and ultimately, premature turbine failure. By choosing 3D Industrial Service, you ensure your turbines deliver consistent, optimal performance throughout their operational lifespan.

Comprehensive turbine alignment

3D Industrial Service provides meticulous alignment services for gas and steam turbines across various turbine models, including popular series such as 7F, 7B, 7E, and 7EA. Our extensive experience enables us to address alignment challenges unique to each turbine model, ensuring the highest levels of accuracy and reliability.

Gas Turbine Alignment & Turbine Generator Alignment

We offer specialized gas turbine alignment and comprehensive turbine generator alignment services, including partial disassembly when necessary. This ensures turbine rotors, compressors, and stationary components are precisely aligned, significantly enhancing turbine reliability and efficiency.

Our detailed alignment approach also effectively manages casing slippage, a common challenge that can significantly impair turbine function. By carefully aligning and securing casings, we prevent displacement and maintain the structural integrity and performance of the turbine.

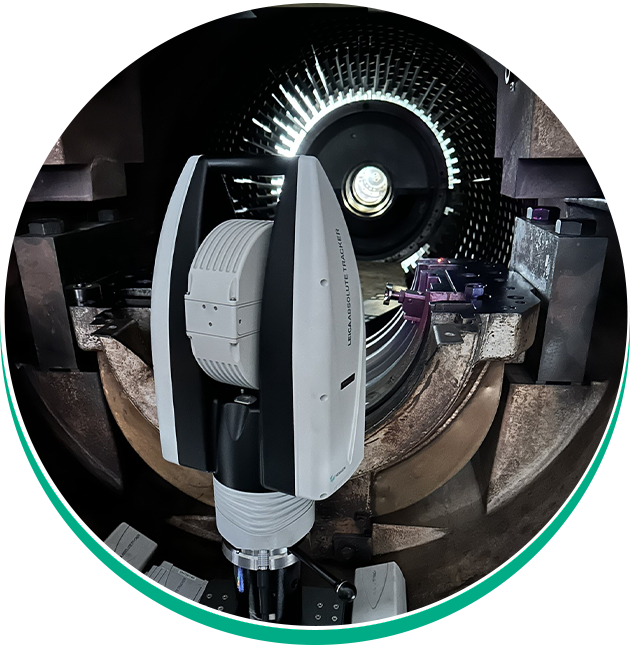

Precision Laser Alignment Systems

Leveraging advanced laser systems and laser trackers, our team surpasses traditional alignment methods. Unlike older methods relying solely on dial indicators, gauges, feeler gauges, and multipoint sets of readings, our laser alignment minimizes sag, distortion, and ensures turbines are aligned for optimal performance.

Precision laser alignment systems offer numerous advantages over traditional methods, including faster execution, more accurate data collection, and reduced downtime. 3D Industrial Service’s advanced technology enables us to capture real-time alignment data, allowing for immediate adjustments and eliminating guesswork in the alignment process.

Specialized services for gas and steam turbines

Our alignment experts, including seasoned millwright professionals, address critical path challenges, eliminating issues such as casing alignment errors, turbine-generator misalignment, compressor inefficiencies, and rotor-stator clearances. Whether your turbine requires full or partial disassembly, our skilled technicians ensure precise, efficient alignment for optimal performance.

3D Industrial Service’s team understands the importance of minimizing downtime and maintaining continuous power generation. Therefore, we strategically plan our alignment services to align with your scheduled outages, ensuring minimal disruption and maximum operational continuity. Our professionals meticulously handle every component, from casing halves and bearing housings to compressor rotors and stationary components, ensuring all alignment tasks meet rigorous performance criteria.

Our team diligently manages the potential for structural distortion or deviation in turbine components during alignment. By controlling sag and flatness deviations, we ensure precise alignment without compromising the structural integrity of critical turbine parts.

Our Turbine Alignment Process

Our alignment process combines innovative and traditional alignment methods, customized specifically for gas and steam turbine internal alignment:

Pre-AlignmentInspection

A comprehensive evaluation of casing alignment, internal alignment, welded joints, dowel pins, and clearances to identify any preliminary misalignment. This proactive approach allows for targeted corrections and mitigates potential issues during the alignment.

Precision

Rotor Positioning

Accurate measurement and precise adjustment of rotor position, axial and radial alignment, and rotor-stator clearance using advanced laser and dial indicators. This step ensures the rotor and stationary components operate harmoniously, significantly reducing friction and enhancing performance.

Bearing and Coupling

Alignment

Bearings and couplings are critical components whose alignment directly influences turbine reliability and longevity. Our meticulous alignment procedures reduce vibration, eliminate blade rubs, and prolong equipment lifespan.

Final Alignment

Verification

Comprehensive data collection to confirm alignment accuracy. Alignment data is rigorously compared against OEM specifications, ensuring all components remain within acceptable tolerances. This verification guarantees operational efficiency and compliance with industry standards.

Benefits of Precision Turbine Alignment

Increased Efficiency

Precise alignment significantly boosts turbine performance and efficiency, optimizing power output and minimizing fuel consumption.

Enhanced Reliability

Reducing the likelihood of unexpected outages and downtime through proactive alignment measures, thereby enhancing the overall reliability of your power generation systems.

IMproved lifecycle performance

Prolong the operational life of turbines by maintaining turbine-generator alignment and ensuring components remain within OEM tolerances.

Cost Reduction

Accurate alignment reduces maintenance costs and prevents costly repairs or premature replacements of turbine components.

Trusted Alignment Service Providers

3D Industrial Service’s reputation as a trusted provider of gas and steam turbine alignment services is built on years of delivering consistently high-quality solutions to industrial facilities across various sectors. Our comprehensive alignment solutions have successfully serviced numerous turbines, reinforcing our position as a leader in the industry.

When precision, reliability, and efficiency matter, 3D Industrial Service’s turbine alignment services deliver exceptional outcomes. Let us support your facility’s long-term operational success through dedicated, professional turbine alignment solutions.

Frequently Asked Questions

Precision Measurements

Enhance turbine performance and protect your investment

3D Industrial Service’s reputation as a trusted provider of gas and steam turbine alignment services is built on years of delivering consistently high-quality solutions to industrial facilities across various sectors. Our comprehensive alignment solutions have successfully serviced numerous turbines, reinforcing our position as a leader in the industry.

When precision, reliability, and efficiency matter, 3D Industrial Service’s turbine alignment services deliver exceptional outcomes. Let us support your facility’s long-term operational success through dedicated, professional turbine alignment solutions.