Semiconductor Facilities –Ensuring Precision & Efficiency

At 3D Industrial Services, we provide precision alignment, maintenance, and installation solutions tailored to semiconductor manufacturing facilities, ensuring high-performance production, contamination control, and strict compliance with industry standards. Whether your facility includes cleanrooms, wafer fabrication plants, or semiconductor assembly lines, our expertise helps you minimize downtime, enhance precision, and maintain a controlled environment for optimal production.

Industries We serve

The semiconductor industry demands extreme precision, contamination control, and equipment reliability to maintain consistent yields and high-quality production. Our specialized services help semiconductor manufacturers optimize production efficiency and ensure compliance with cleanroom regulations.

Wafer Fabrication Facilities

Semiconductor Packaging & Assembly

Controlled Environment Manufacturing

Microelectronics Production

Photovoltaic & LED Fabrication Plants

Electronic Component Manufacturing

Semiconductor R&D Labs

And More

How Do We Support the Semiconductor industry?

Semiconductor facilities require micron-level alignment, vibration control, and contamination-free environments to prevent production defects, inefficiencies, and equipment failures. Our alignment, vibration analysis, and cleanroom-compliant services help optimize lithography, etching, deposition, and assembly processes.

Key Challenges We Solve:

Precision Equipment Alignment for Semiconductor Fabrication

Vibration & Thermal Expansion Control for High-Precision Manufacturing

Contamination Risk Reduction in Cleanroom Environments

Ensuring Accuracy in Robotic & Automated Semiconductor Assembly

Compliance with ISO 14644, SEMI, and Industry Cleanroom Standards

Our Specialized Services for the Semiconductor Industry

3D Laser Scanning

Ensures precision facility planning and contamination-free integration.

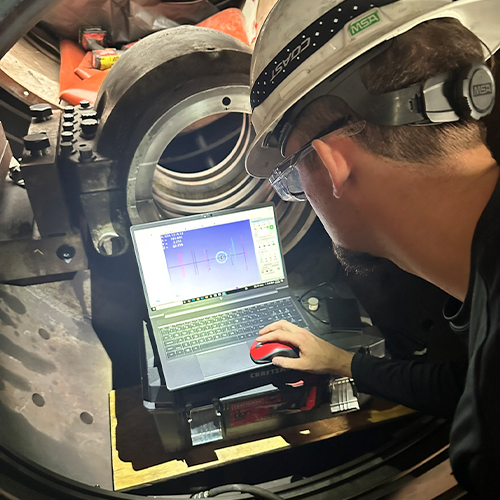

Equipment alignment

Reduces defects, improves efficiency, and enhances semiconductor yields.

Vibration analysis

Ensures stability for lithography, metrology, and deposition processes.

mechanical millwright

Precision adjustments optimize reliability and repeatability.

Welding & Fabrication

Custom sanitary welding ensures contamination-free processing.

Industrial Insulation

Regulates temperature-sensitive semiconductor fabrication environments.

heat trace systems

Ensures stability for critical semiconductor processing conditions.

sandblasting

Prepares surfaces while maintaining strict contamination control.

Why Choose 3D Industrial Services?

When precision, contamination control, and efficiency are critical, 3D Industrial Services delivers advanced alignment, maintenance, and installation solutions to keep semiconductor production running smoothly. Our highly trained specialists ensure regulatory adherence, minimal downtime, and maximum system efficiency.

Industry-Specific Expertise & Regulatory Compliance

Advanced Precision Solutions

Reliability & Contamination Prevention Focus

Customized Solutions for High-Tech Manufacturing

FAQ About semiconductor facility solutions

Proper alignment prevents micron-level misalignment, vibration interference, and defects, ensuring higher semiconductor yields and precision production.

Semiconductor facility services

get a free consultation

Precision misalignment, vibration interference, and contamination risks can compromise semiconductor production quality. Ensure your facility operates at peak efficiency with expert alignment, maintenance, and installation solutions tailored for semiconductor fabrication and assembly.