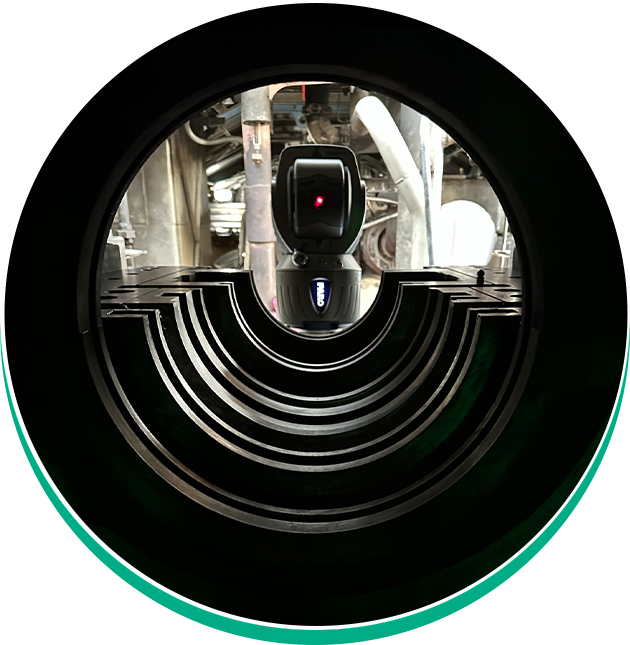

Ensure optimal performance, reduce downtime, and save both time and money by utilizing professional alignment services from 3D Industrial Service LLC. Our specialized mechanical machine alignment services and mechanical repair services focus on high precision alignment and corrective maintenance for various industrial machinery. Misalignment, vibration, and inadequate lubrication are among the leading causes of machinery breakdown and excessive downtime. Our expert technicians use state-of-the-art laser alignment and diagnostic techniques, including infrared and vibration analysis, to deliver reliable preventative maintenance and precision alignment solutions tailored specifically to your industry needs.

comprehensive industrial machinery alignment solutions

3D Industrial Service LLC provides a wide array of alignment services designed for industrial machinery across numerous industries, including aerospace, automotive, power generation, petrochemical, and rail sectors. Our professional technician team delivers precision equipment alignment, shaft alignment, and internal alignment services to significantly enhance machinery reliability and efficiency. Laser alignment for rotating equipment, including compressors, pumps, turbines, and machine tools, is a core competency, helping you meet stringent OEM specifications and ISO standards.

Our industrial laser alignment services incorporate detailed inspection, module calibration, and balance adjustments, ensuring machinery alignment meets or exceeds OEM acceptance testing requirements. Whether your machinery needs an overhaul, rebuild, installation, or calibration, our technicians deliver comprehensive service, from fabrication through commissioning.

laser and precision alignment services

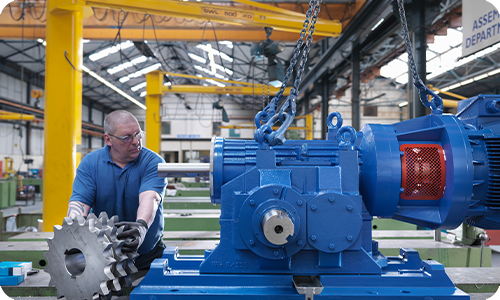

We specialize in high precision laser alignment services for industrial machinery, including shafts, bearings, couplings, reducers, and rotating equipment. Precision alignment reduces vibration, minimizes thermal expansion stresses, and extends the life of critical components such as babbitt bearings. Proper alignment ensures smoother equipment operation, lower energy consumption, and reduced mechanical wear, providing direct savings in both time and money.

Mechanical Diagnostic, Repair, and Maintenance Services

Our mechanical repair services extend to mechanical equipment overhaul, reconditioning, dynamic balancing, and preventive and predictive maintenance. We perform laser alignment, quality parts replacement, and in-house repairs for machinery modules, including reciprocating compressors, steam turbines, and diesel engines. Our advanced maintenance and repair services encompass oil analysis, brake inspections, and diagnostic scans, ensuring machinery operates at peak reliability.

Our industrial alignment and mechanical adjustment process

Our structured alignment process involves the following key steps:

Initial Diagnostic

Inspection

Precision Alignment

Measurement

Using pro laser alignment technology, metrology tools, and high precision equipment, we accurately measure shaft alignment, coupling levels, and internal alignment parameters.

Corrective Mechanical

Repair

Execute necessary corrective mechanical repairs, rebuild, grind, and recondition components to OEM specification.

Post-Repair

Acceptance Testing

Conduct comprehensive acceptance testing, dynamic balancing, and equipment calibration to ensure machinery reliability and performance meet industry standards.

Benefits of industrial alignment and mechanical adjustments

improved machinery reliability

Accurate alignment and balance reduce vibration and misalignment-related wear, improving overall equipment reliability.

Cost Reduction

Preventative and predictive maintenance significantly decrease the likelihood of costly emergency repairs and downtime.

Enhanced operational safety

Precise equipment alignment and rigorous mechanical inspection reduce safety risks associated with machinery failures.

Optimized performance

Laser alignment ensures mechanical equipment operates efficiently, meeting OEM specifications and ISO standards.

Applications and industries served

Our structured alignment process involves the following key steps:

Power Generation

And Petrochemical

Precision alignment and turbine repair services for steam turbines, compressors, pumps, and reciprocating machinery.

Automotive

and Aerospace

On-site laser alignment and mechanical repair services for rotating equipment, brake systems, and module installation.

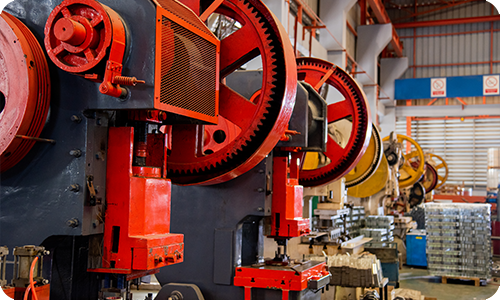

Manufacturing and

Fabrication Facilities

Preventative and predictive maintenance, laser alignment, and overhaul services to maintain production machinery at optimal levels.

Frequently Asked Questions

Optimize Performance

Why choose 3d Industrial Services?

Our team at 3D Industrial Service LLC is your trusted integrator for precision mechanical alignment, machinery alignment, and mechanical repair. Leveraging our extensive industry expertise, cutting-edge technology, and comprehensive service offerings, we ensure your industrial machinery achieves maximum reliability, operational excellence, and cost-effective performance. Trust us to perform your next alignment or repair service, and experience firsthand the benefits of superior mechanical precision.